In my car it is a quality AMP product. I have no idea if it is original, but it may not be since I have a Lada after market ignition switch.

It is a terrible choice for an automotive application, because it is NON-LOCKING. This is probably the root of the whole problem. And after 36 years (if original) the plastic has distorted to the point that it doesn't mate very well.

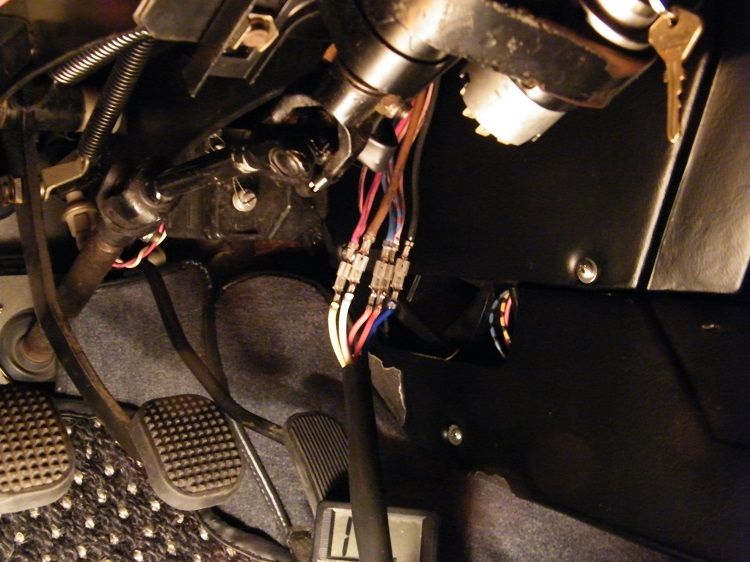

So I pulled all of the connections from the block. They come out by inserting a very small flat tab screwdriver in to release the locking tab on each crimped connector that the housing holds. A few of them would not release under any circumstance, so the connector housing was cut away. I found a few of the connections to be made quite loosely. This is an obvious source of the click of death problem.

Oddly enough, all of the crimp connections on both sides were solid, have no corrosion, and passed heavy pull test easily.

Ohmed out across the connections at about 0.2 or 0.3 ohm before tightening them up, 0.0 ohm afterwards (DVM). I tighten them up by crimping in the wings on the female side, after wire brushing the male side.

So what to do about this thing?

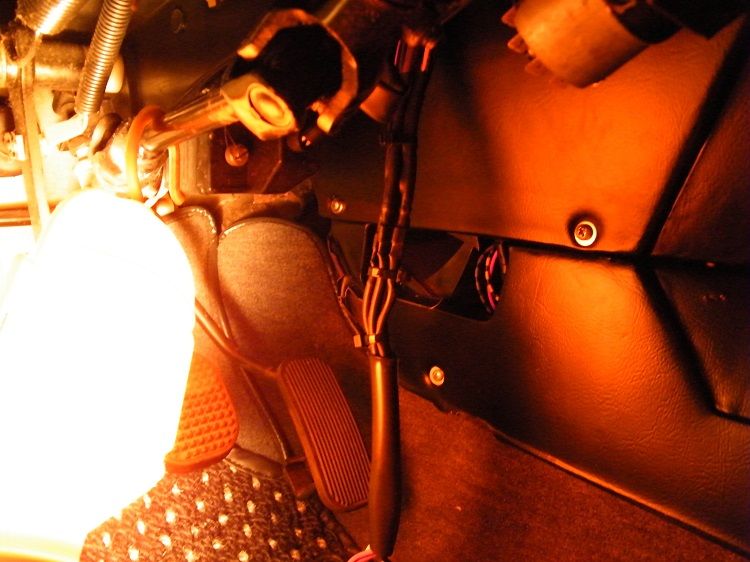

Well, I decided to clean up the connections, tighten them up, and reassemble the existing connections individually, with heat shrink tubing to hold them in place this time. It is reversible if it fails, and I didn't like the idea of doing a whole bunch of apparently needless soldering on my back under the dash in an unheated garage. I bundled the set together tightly with ty-wraps and routed it all properly back up under the dash. I will let you know how it works when I restart the engine in a day or two. Have done a bunch of other stuff as well in the engine bay, not quite ready to fire it up.